Motor Spindle Safety System

The unique motor spindle protection system with all-round protection in the event of overload and collision.

Background: Collisions in machine tools

Collisions in machine tools have many causes:

– Operating and programming errors

– Interfering contours

– Incorrectly set zero points

– Power failure

In practice, collisions often occur when a CNC program is executed for the first time.

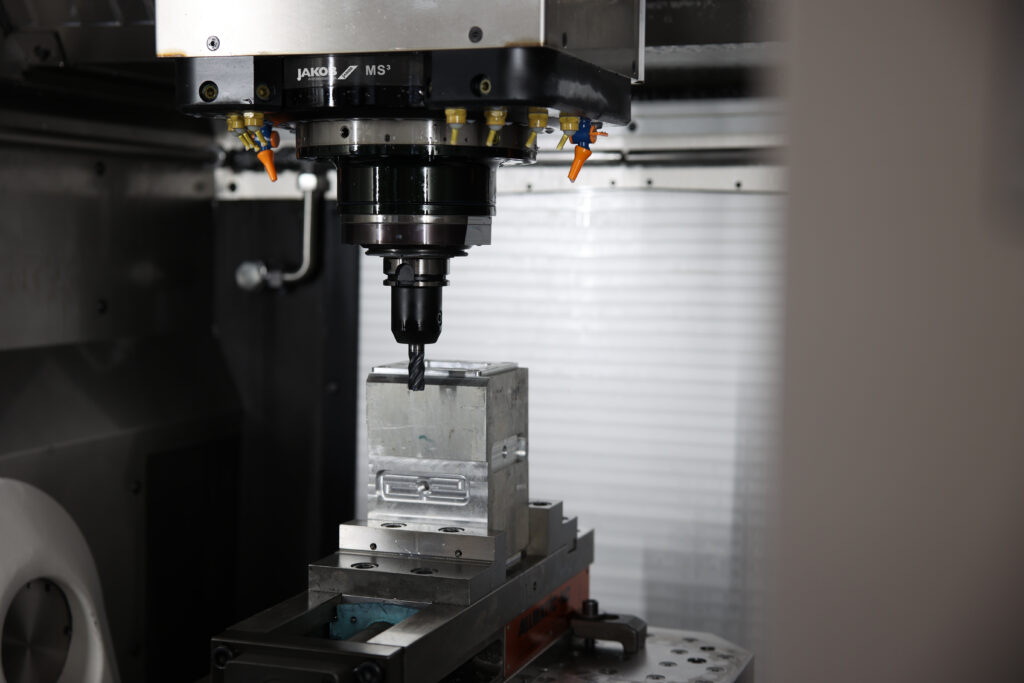

To avoid damage, the MS³ motor spindle protection system offers the best possible safety for the CNC machine tool.

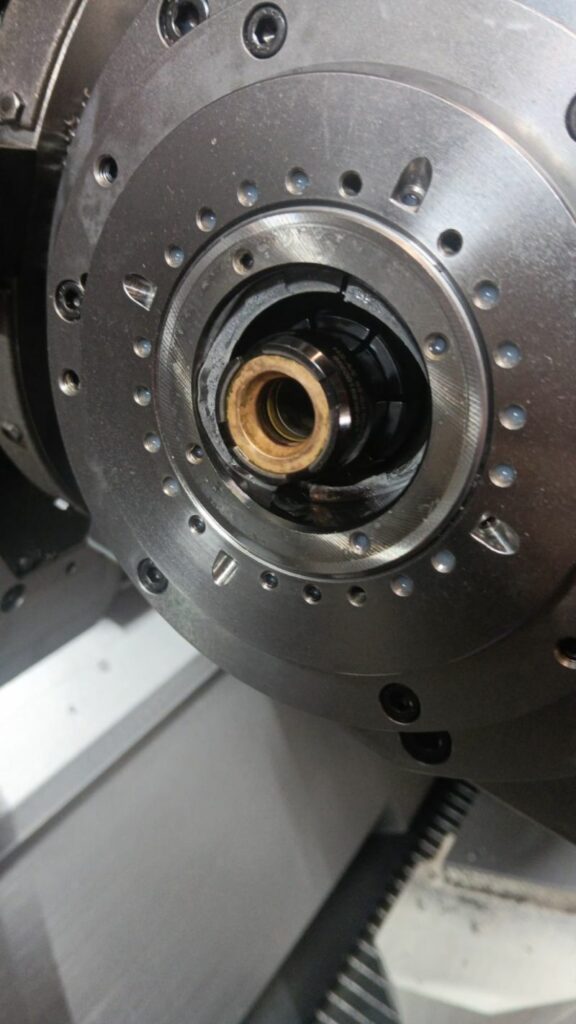

Image source: OTT Jakob/Linkedin

A collision without protection means

- Motor spindle damaged

- Machine accuracy adjusted

- Production interruption

- High repair costs

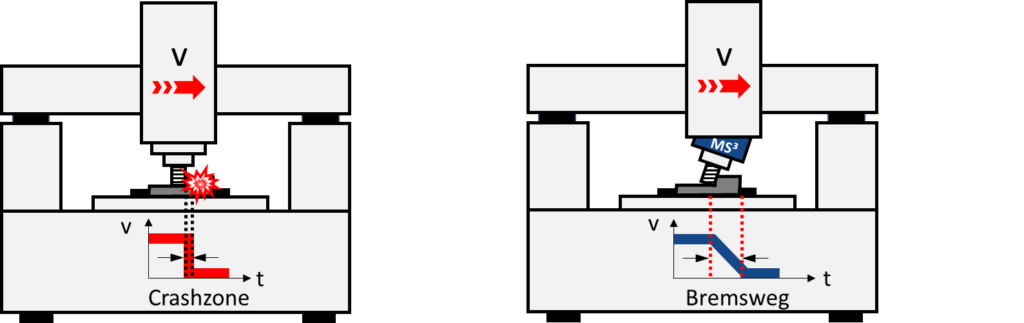

The crash protection MS³ offers

- Hybrid protection: braking distance + signal

- Absorption of collision energy

- Protection in all axial directions

- Responsive action

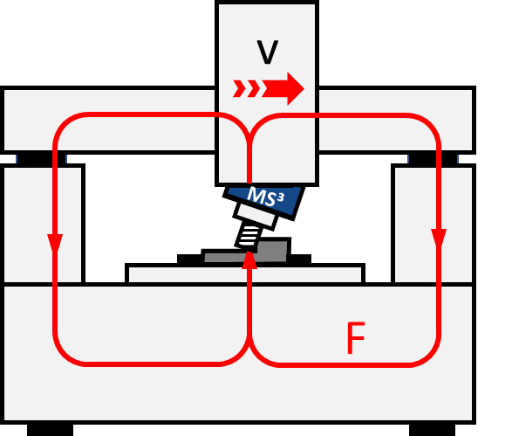

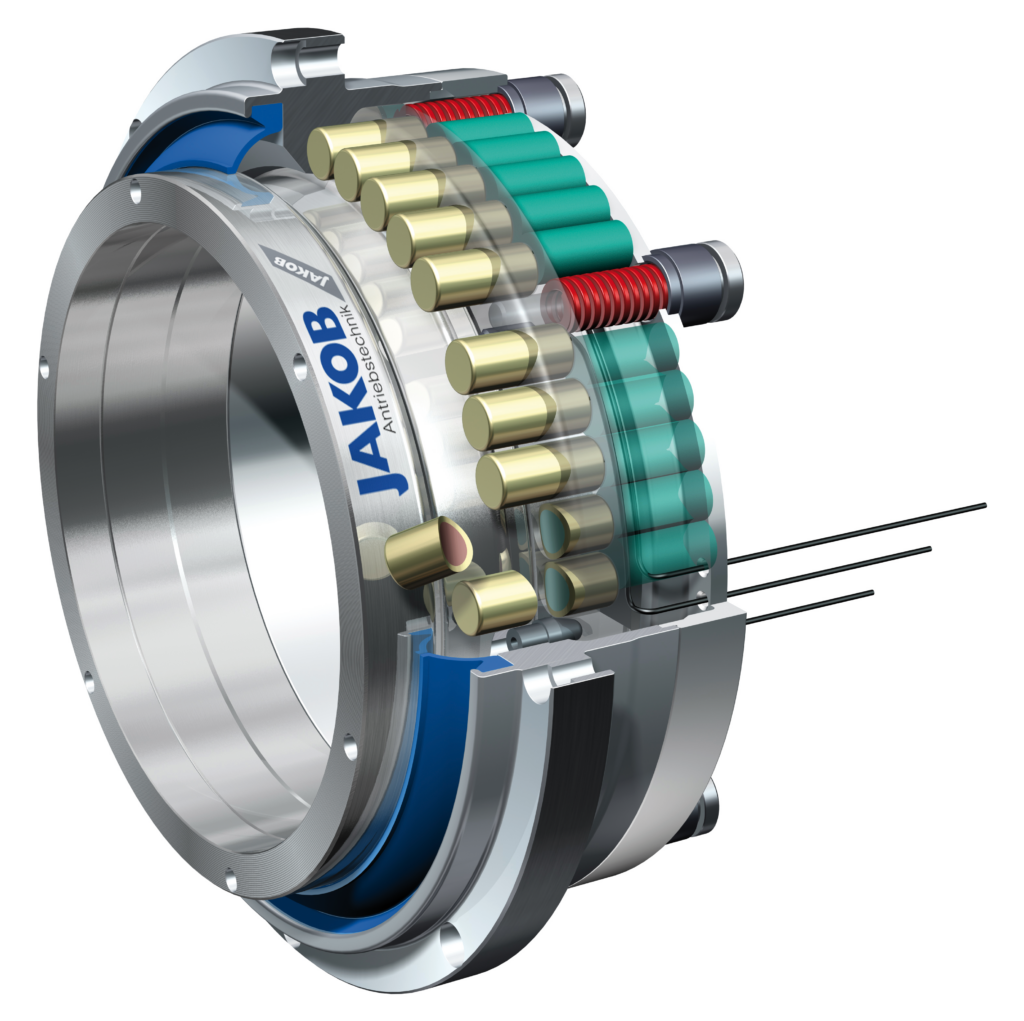

The structure of the motor spindle protection system MS³

- Integrated double flange system with connection to spindle and machine

- Magnets in the joint provide high holding force and rigidity

- Suspension for shock absorption and automatic reset of the motor spindle

- Joint design ensures high re-engagement precision

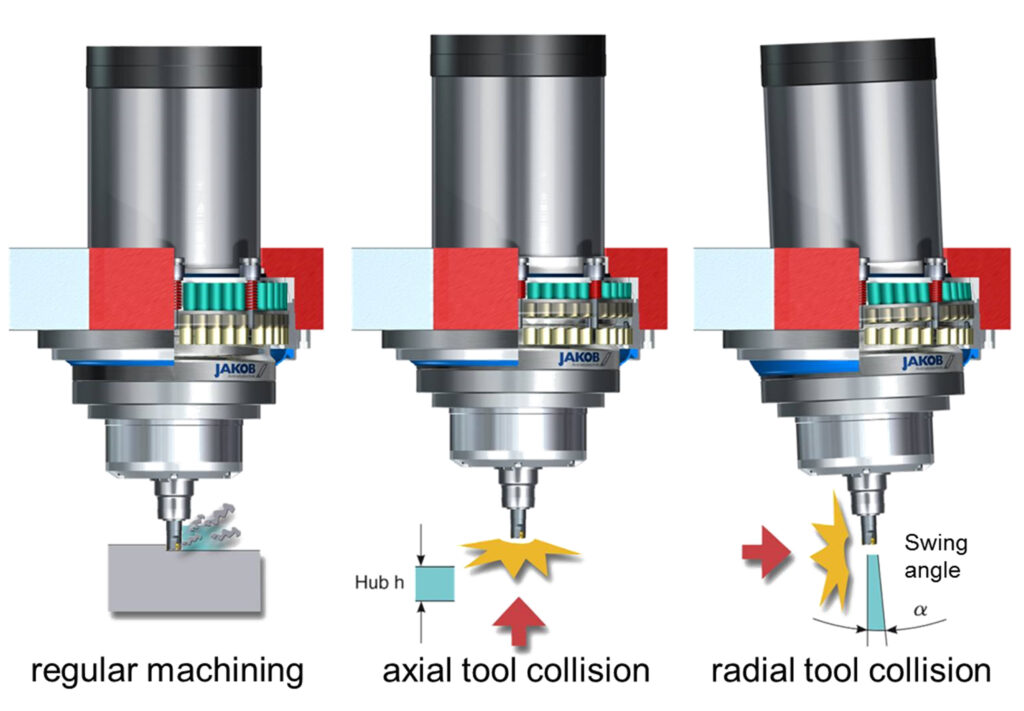

The protective function

Magnets ensure cohesion in the MS³ motor spindle protection system. In a collision situation, i.e. H. When a critical overload force is reached, the protection system interrupts the force flow of the motor spindle and machine and effectively dampens the shock. As a result, the damage-relevant force peaks of the collision do not affect the shock-sensitive components of the motor spindle such as the ball bearings.

Due to the additional axial or radial deflection distance of the spindle, depending on the overload situation, the machine’s axis drives gain the necessary braking distance for automatic emergency braking from high processing speeds.

The replacement and repair of the spindle are avoided. The geometry of the machine is not adjusted. The MS³ protection system works direction-independent and non-destructive. After the axes have been moved free, the protection system returns to its original position and the machine can continue producing.

The advantages

- Protected machine tool and motor spindle

- Maintaining machine accuracy

- Full availability

- After the crash: restart and calibration without long downtime

The facts

- The protection that is always active

- Unlimited roughing performance

- Maintenance-free and indestructible

- Adaptable to all common motor spindles

The voices from practice

“On average, there are 2-3 collisions during the lifetime of the machine tool.”

“The investment in MS³ pays off with the first collision.”

“It actually works!”

100% machine availability guaranteed after a collision!