Home > Vacuum Technology

Innovative solutions for your vacuum technology

ISO-KF

- Pressure range: Up to 1×10-8 hPa as standard (with O-rings), with metal seals even up to 1×10-9 hPa for ultra-high vacuum applications.

- Areas of application: Vacuum coating industry, chemical industry, medicine, food technology, semiconductor industry and research.

- Sealing materials (EPDM, FKM, NBR)

- Standard: Complies with DIN 28403 and ISO 2861

ISO-K

- Pressure range: Up to 1×10-8 hPa as standard (with O-rings), with metal seals even up to 1×10-9 hPa for ultra-high vacuum applications.

- Areas of application: Semiconductor industry, laser technology, medical technology, laboratories and research.

- Sealing materials (EPDM, FKM, NBR)

- Standard: Complies with DIN 28404 and ISO 1609 standards.

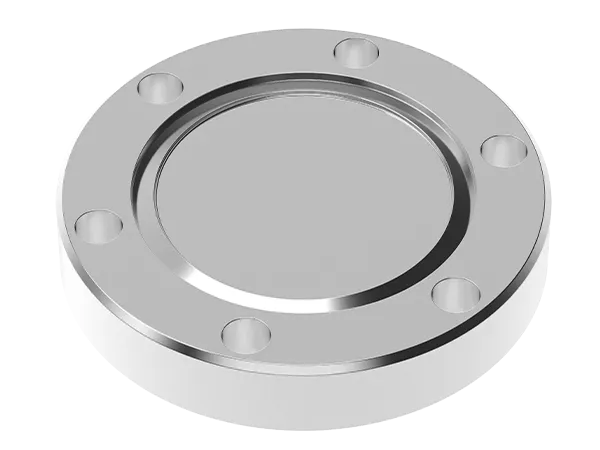

CF

- Pressure range: up to 1 x 10-12 hPa

- Fields of application: Vacuum coating industry, surface analysis and research

- Standard: Complies with the ISO 3669 standard

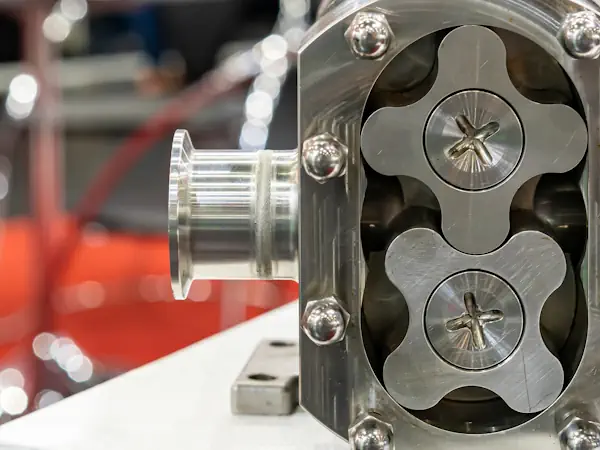

Valves

- DN range: Available for KF DN 10-50 and for ISO-K flanges from DN 63-160

- Temperature range: up to 150°C

- Areas of application: Semiconductor industry, food and chemical industry and research

Vacuum pump accessories

- Gas lock offers an easy way to re-evacuate containers.

- Vacuum pump protection: Adsorption and cold traps as well as condensate separators protect vacuum pumps from contamination and backflowing vapors.

- Clean vacuum environment: These components are crucial for generating and maintaining oil-free high and ultra-high vacuum.

- Reduced maintenance: Protecting the systems from contamination significantly reduces maintenance costs.

Services

Vacuum brazing using the brazing process

– No oxidation

– Flux-free

– Low distortion due to uniform heating in the furnace

Vacuum annealing

– Reduce / relieve internal stresses in the material

– Oxidation-free

– Residue-free, no scale formation

Vacuum welding

– Using the TIG process

Leak test

– Helium leak test

Glass bead blasting

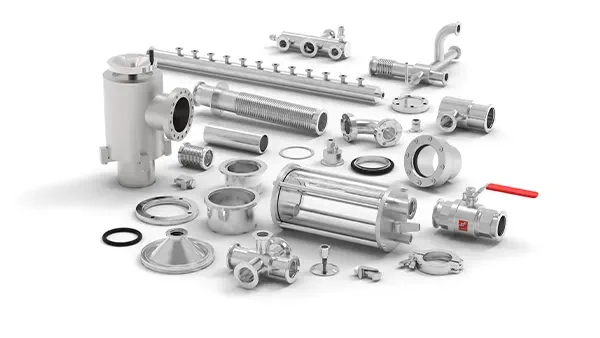

Over 1000 standard components available

A reliably functioning vacuum system consists of various precisely manufactured vacuum components. As a specialist with many years of experience, JAKOB Antriebstechnik offers components of the KF, ISO-K and CF standards according to customer-specific requirements. In addition to machining, TIG and plasma welding as well as vacuum brazing and annealing are available as manufacturing processes. In addition to customer-specific production, Jakob also offers an extensive catalog range, including vacuum lines, special connections from vacuum flanges to pipe fittings, valves, gas locks, zeolite and cold traps as well as condensate separators.

© 2025 Jakob Antriebstechnik GmbH. All Rights Reserved.