JAKOB Antriebstechnik GmbH

From manufacturer to innovation partner – quality for over 50 years

Drive Technology

Large selection of metal bellows, elastomer-, stainless steel-, miniature-, safety- and distance couplings as well as individual special designs for all areas of application.

Clamping Technology

Our range includes mechanical clamping elements with force amplification, hydromechanical spring clamping systems and clamping hydraulics.

Drive Technology

From coupling manufacturer to innovation partner

Metal Bellows Coupling

Metal bellows couplings are backlash-free, flexible all-metal couplings with high torsional rigidity and minimal mass moments of inertia.

Various clamping connections and different metal bellows shapes are available for a wide range of applications.

Overcoming distance

Distance couplings, also known as cardan shafts, are servo couplings for large center distances without complex intermediate bearings. A common design feature of the distance coupling is a variable-length intermediate tube that can be optimally adapted to the customer-specific application.

Special solutions

Custom-made products? Quite standard for us! We realize individual solutions from just one piece – please contact us for a personal consultation.

Elastomer couplings

Elastomer couplings are plug-in, backlash-free, flexible shaft couplings for low to medium torques. A polyurethane spider with a high Shore hardness serves as a connecting and compensating element. The elastic star can compensate for minor shaft misalignments, is electrically insulating and has good vibration damping properties.

Miniature series

Miniature couplings are servo compensating couplings used primarily for tachometers, NC axes, stepper motors, potentiometers, rotary encoders, angle encoders, and servo drives.

They are available as torsionally rigid metal bellows couplings, vibration-damped elastomer couplings, or highly compensating cross-slide couplings.

Safety Couplings

As torque limiters and overload protection, safety couplings reliably prevent costly machine damage, repairs, and downtime. If the set torque is exceeded, the drive is mechanically disconnected.

Safety couplings are life insurance for your machine,

regardless of whether the malfunction was caused by incorrect operation, a programming error, material overload, or tool breakage.

Stainless steel versions

JAKOB Antriebstechnik offers many series in stainless steel versions. Resistance to chemicals, such as those used for cleaning in the food industry, is one of the material’s strengths.

Clamping Technology

Technical solutions instead of brute force

Mechanical Clamping Elements

This clamping element group includes mechanical power clamping screws and power clamping nuts. They are designed for manual operation with simple handling, but for very high clamping forces. Various clamping mechanisms such as wedge systems or planetary gears are used for force amplification. used. The robust design, the self-locking function and a high overload capacity

guarantee maximum operational safety.

Force measurement

The holding force of a clamping device during the machining of workpieces is a criterion of outstanding importance. It is decisive for the machining quality as well as for the safety of the machine operator, the workpiece and the machine tool.

Power clamping screw

– mechanical

– hydromechanical

JAKOB power clamping spindles for face plates and clamping plates on vertical, horizontal, center, face and roller lathes as well as grinding and special machines are designed for the highest demands and maximum workpiece weights with the greatest possible operational reliability. They are primarily suitable for installation in claw boxes or for direct mounting in face plates of turning, grinding and special-purpose machines.

Areas of application

Clamping elements or clamping technology from JAKOB Antriebstechnik are used wherever workpieces or tools need to be secured securely and with high clamping forces. Thanks to sophisticated technology, all our clamping elements enable the application of enormous clamping forces, which can hardly or only with great effort be achieved with conventional clamping devices.

Hydromechanical spring clamping systems

The hydromechanical spring clamping systems work in a mechanical-hydraulic interaction. The Clamping force is applied mechanically by a pre-tensioned disk spring assembly. The hydraulics are only

is required for the release stroke of the elements, whereby the tie rod or pressure bolt is released. With this system guarantees a high level of operational reliability, as the clamping force is always maintained at the full leakage losses, the full clamping force is always maintained.

Accessories - Clamping technology as PDF

This clamping element group includes mechanical power clamping screws, power clamping nuts and eccentric block clamps. They are designed for manual operation with simple handling, but for very high loads. clamping forces. Various clamping mechanisms such as wedge systems are used to increase the force, planetary gear or eccentric principle. The robust design, the self-locking function, and a high overload capacity guarantee maximum operational safety.

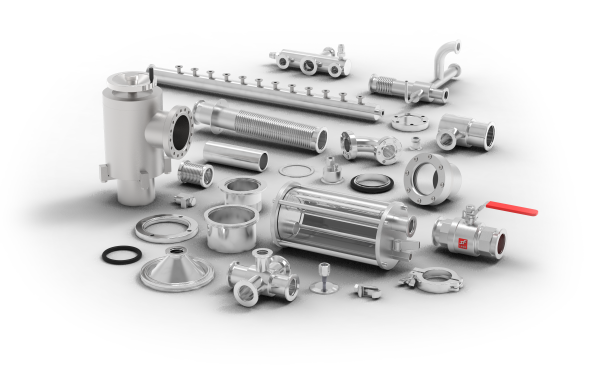

Vacuum technology

Customer-oriented solutions for vacuum components

KF - Small flanges

KF offer quick and easy installation using clamping rings. They are available in the DN range from 10-60 and in various materials (stainless steel/aluminium).

Valves for vacuum components

Valves are indispensable for shutting off or venting areas of a vacuum system and cover a wide vacuum range from rough vacuum to high vacuum. They are available in various designs such as angle valves, ball valves and venting valves and are made of high-quality materials such as stainless steel or brass.

ISO-K flanges

ISO-K flanges are robust vacuum connections that are ideal for low, medium and high vacuum. They cover a wide DN range from 63-630 and are available in stainless steel or aluminium. The connection is made securely using clamp bolts.

Vacuum pump accessories

In vacuum technology, sealing valves together with gas locks are essential for the safe and clean evacuation of evacuated or gas-filled containers. Adsorption traps (zeolite traps) are indispensable for maintaining a clean vacuum, as they prevent the ingress of oil and water vapor and thus improve the performance and service life of vacuum pumps.

CF flanges

CF flanges are the first choice for ultra-high vacuum applications. They are available in the DN range from 16-250. The connection is made via holes in the flange and screw sets that are used for fastening. A special feature here is the cutting edge on the flange and the use of metal gaskets.

Vacuum services

Vacuum brazing using the brazing process, vacuum annealing, vacuum welding using the TIG process, helium leak test, glass bead blasting

Your reliable partner

In 1971, Ludwig Jakob founded the company JAKOB Maschinenteile in Kleinwallstadt as a sideline. Two years later, JAKOB produces resolver gearboxes and simple bellows couplings with keyway connections. One year later, the KSS coupling is developed and patented. With the KSS coupling, the principle of the friction-locked shaft-hub connection is applied for the first time. Even today, this principle has many imitators.

Solutions for your industry

Machine tools

Maximum precision will always play a major role in machine tools. But new topics such as the increasing demand for automation solutions and digitalization are also constantly presenting the industry with new challenges. JAKOB can meet these needs perfectly with high-quality and reliable components for the drive.

Energy technology

Technological change is particularly noticeable in the energy sector, with new challenges arising time and again, not least due to renewable energies. At the same time, systems must be particularly protected against failure in order to ensure a constant energy supply. This is why the fail-safe design of our drive units, such as distance couplings, bellows couplings and elastomer couplings, is our top priority.

Medical technology

The production of medical supplies such as medicines must be as sterile and germ-free as possible. Special attention is also paid to hygienic surfaces in the applications of medical machines or containers. JAKOB Antriebstechnik has a broad portfolio of stainless steel products for precisely these cases, both in clamping technology and in the field of drive technology.

Food industry

Components and systems in the food industry are subject to the constant influence of dirt, dust and aggressive cleaning agents. For this reason, attention must be paid to the “easy to clean” feature right from the design stage. At JAKOB, special components are designed in such a way that there are few to no undercuts on the surface of the components in order to keep cleanability as high as possible (hygienic design). Strict attention is also paid to the roughness of the surface in order to prevent microorganisms from settling.

Forming industry

An efficient press line is a key success factor in forming technology; process optimizers talk about the cost per stroke of a workpiece such as a car body part. In order to remain competitive, it is therefore important to reduce the costs of the system, especially the main and auxiliary times.

Servo industry

In the servo sector, servo motors are used to move and position machine parts with absolute precision. This places high demands on the drive train and its individual components.

Packaging machines

A packaging machine stands for much more than just packaging products. Other tasks such as sorting, printing, stacking and more are also required of the systems. The machines are used in harsh mechanical engineering environments as well as in absolutely clean chemical or food environments. As a packaging machine always has to take on additional tasks, the aim is to design the machines to be as modular as possible. This allows the user to combine different modules to create the perfect solution.

Customer service always there for you - personally and directly

Do you have a technical or commercial question? Contact us – simply by phone, email or live chat. Our team is always available for you and will support you quickly and reliably.