Index > Solutions for your industry > Servo industry

Servo industry

In the servo sector, servo motors are used to move and position machine parts with absolute precision. This places high demands on the drive train and its individual components.

In automation technology, machine parts such as grippers on a robot arm are accelerated and decelerated very quickly, resulting in high overload and holding torques in the drive. To meet these requirements, JAKOB Antriebstechnik offers servo couplings with bellows or compensating carbon tubes. This compensates for any misalignment in the input and output, while at the same time ensuring that the rotary movement is absolutely angularly synchronized. In addition, any heat generated during operation must be taken into account. Aluminum components are replaced with steel or stainless steel components for certain applications. The ‘smart’ servomotor in combination with high-quality components is also ideally suited to the requirements of Industry 4.0.

Areas of application: – Inking rollers for printing machines – Industrial robots – Tool changers – Rotary tables

Examples of applications in the servo industry

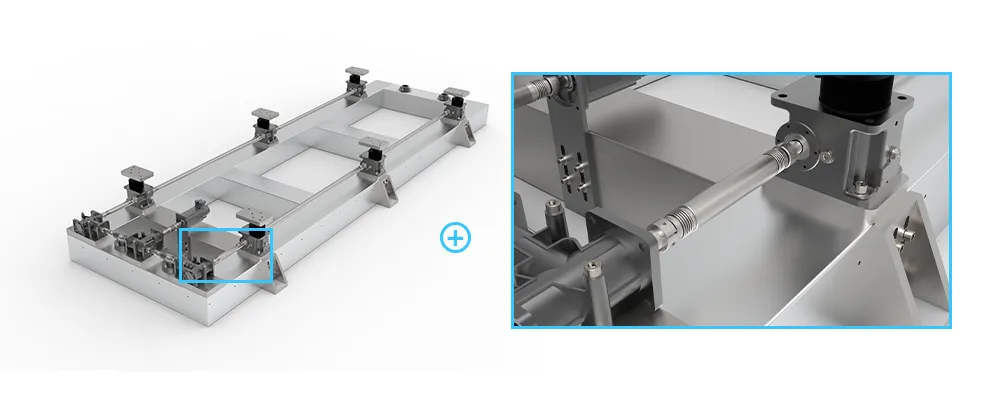

Use of distance couplings in a lift table

Our product portfolio for the servo industry

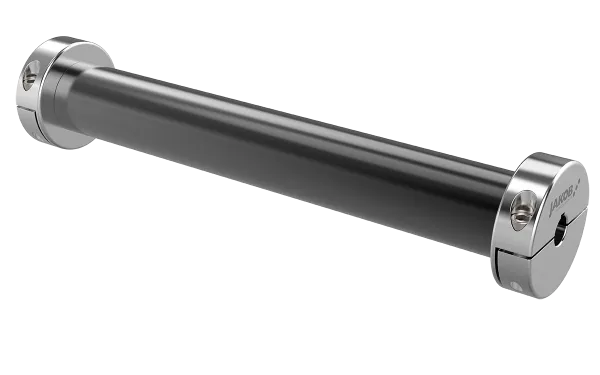

Distance couplings

– variable lengths up to 6m

– high torsional rigidity

– low moments of inertia

– high speeds

– temperatures up to 300° C

Bellows couplings

– Torques up to 50,000 Nm

– High torsional rigidity

– Temperatures up to 350°C

– High speeds

– Optional stainless steel version

Miniature couplings

– Vibration-damping (with elastomer spider)

– high temperatures (with metal bellows)

– large shaft misalignment possible (cross-slide coupling)

– blind mounting (with elastomer spider)