Home > Clamping Technology

Clamping elements

Mechanical Clamping Elements

This clamping element group includes mechanical power clamping screws and power clamping nuts. They are designed for manual operation with simple handling, but for very high clamping forces.

Various clamping mechanisms such as wedge systems or planetary gears are used for force amplification. The robust design, self-locking function and high overload capacity guarantee maximum operational safety.

Features:

– maximum clamping forces

– high operational reliability

– simple manual operation

– compact design

Power clamping screw

– mechanical

– hydromechanical

JAKOB power clamping screw for face plates and clamping plates on vertical, horizontal, center, face and roller lathes as well as grinding and special machines are designed for the highest demands and maximum

workpiece weights with the greatest possible operational safety. They are primarily suitable for installation in jaw boxes or for direct mounting in face plates of lathes, grinding and special-purpose machines.

Features:

– very high clamping forces

– maximum operational reliability

– large power clamping stroke

– simple operation and assembly

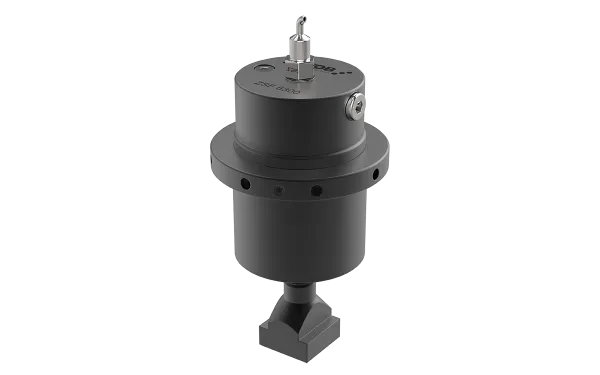

Hydromechanical spring clamping systems

The hydromechanical spring clamping systems work in a mechanical-hydraulic interaction. The clamping force is applied mechanically by a pre-tensioned disk spring assembly. The hydraulics are only required

for the release stroke of the elements, which releases the tie rod or pressure bolt. This system ensures a high level of operational reliability, as the clamping force is always maintained at the full level regardless of oil pressure or leakage losses.

Features:

– mechanical clamping – hydraulic release

– maximum operational reliability

– leak-proof and robust

– economical clamping technology

Force measurement

The holding force of a clamping device during the machining of workpieces is a criterion of outstanding importance. It is decisive for the machining quality as well as for the safety of the machine operator, the workpiece and the machine tool.

High clamping force - low tightening torque

Clamping elements or clamping technology from JAKOB Antriebstechnik are used wherever workpieces or tools need to be secured securely and with high clamping forces. Thanks to sophisticated technology, all our clamping elements enable the application of enormous clamping forces, which can hardly or only with great effort be achieved with conventional clamping devices. The tightening torques for our mechanical clamping devices are multiplied by our patented force amplifiers, while the clamping forces for the other assemblies are generated hydraulically, hydro-mechanically or pneumatically.

Purely mechanical clamping elements can be found in our power clamping nuts and bolts. These products are able to replace their conventional versions (conventional nuts and bolts) and make work considerably easier, especially when high clamping forces are absolutely necessary. Thanks to force amplifiers, massive clamping forces can be achieved with an Allen key (MDA series), wrench (MCA, MCG, SC series) or by hand with an integrated star or T-handle (MCA-S or MCA-T series). However, JAKOB recommends the use of torque wrenches to avoid exceeding the permissible nominal tightening torque and damaging the mechanics. When used correctly, mechanical clamping elements are maintenance-free.

Power clamping spindles from JAKOB Antriebstechnik are used to generate clamping forces in face plates or claw boxes and are available in mechanical (MSP and MSPD series) and hydro-mechanical (HSP series) versions. They replace solid spindles and allow the required clamping forces to be generated much more easily and efficiently.

Hydromechanical spring clamping systems (ZSF and ZDF series), or so-called spring clamping and spring pressure cylinders, work with a combination of mechanics and hydraulics. The clamping forces are applied mechanically using disk spring assemblies; the costly hydraulic pressure is only required to release the cylinders. This has another significant advantage: the clamping elements remain securely clamped even if the pressure drops, so safety is not compromised. Hydromechanical spring clamping systems are suitable for slide or tailstock clamping.