Home > Clamping Technology > Mechanical Clamping Elements

Mechanical Clamping Elements

The main design feature of the series MCA, MCG, MDA and MDR series is an integrated transmission gearbox for the multiplication of the manual tightening moments. This provides the user with very robust and flexible clamping elements are available, which provide clamping forces with simple manual operation and maximum operational reliability. The series MCA and MCG are available with blind hole thread or threaded and centrally arranged hexagon socket, the MDA and MDR series with through-hole thread thread and laterally offset or radially arranged hexagon socket. The power clamping nuts can be for a wide range of clamping tasks throughout the construction, for example for tool clamping in presses and punching presses.

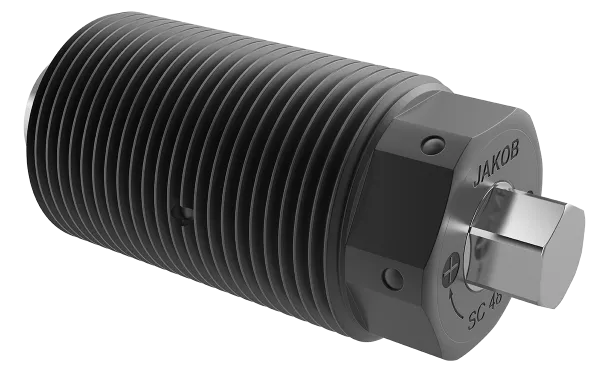

MDR - Power Clamping Nut

– lateral operation

– MDR with through-hole thread

MCA - Power Clamping Nut

– high clamping forces – low tightening torques

– with blind hole thread – thread protected

– centric operation

– compact design – up to 400° C

MCA-DB - Power Clamping Nut

– with integrated torque limiter

– prevents overloading of the clamping nut

– simple operation with a wrench

(no torque wrench required)

– high clamping forces – low tightening torques

– compact design – up to 400° C

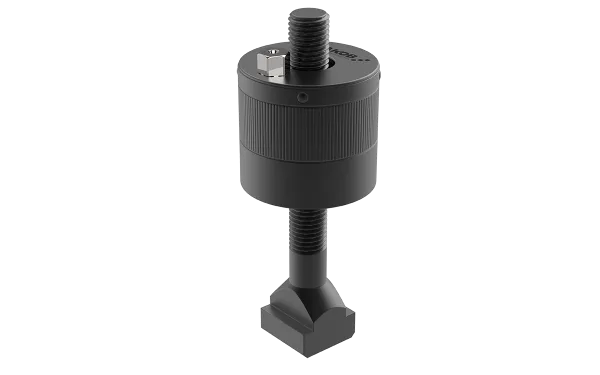

MDA - Clamping Nut

– high clamping forces – low tightening torques

– with through-hole thread

– for variable clamping edge height

– unlimited clamping stroke

MCA-S / MCA-T - Power Clamping Nut

– simple manual operation with handle

– quick feed thanks to automatic switchover

MCG - Power Clamping Nut

– function as power clamping screw

– with threaded bolts M12 to M64

– centric operation

– compact design

– 4 sizes up to 200 kN

– no need for interfering stud bolts

MCF-VA - Stainless Steel Clamping Nut

– high clamping forces – maximum operational reliability

– no loss of clamping force due to temperature fluctuations

– simple operation – accident prevention

– low thread friction – minimized wear

– robust, compact stainless steel design

– high operating speeds and balancing quality