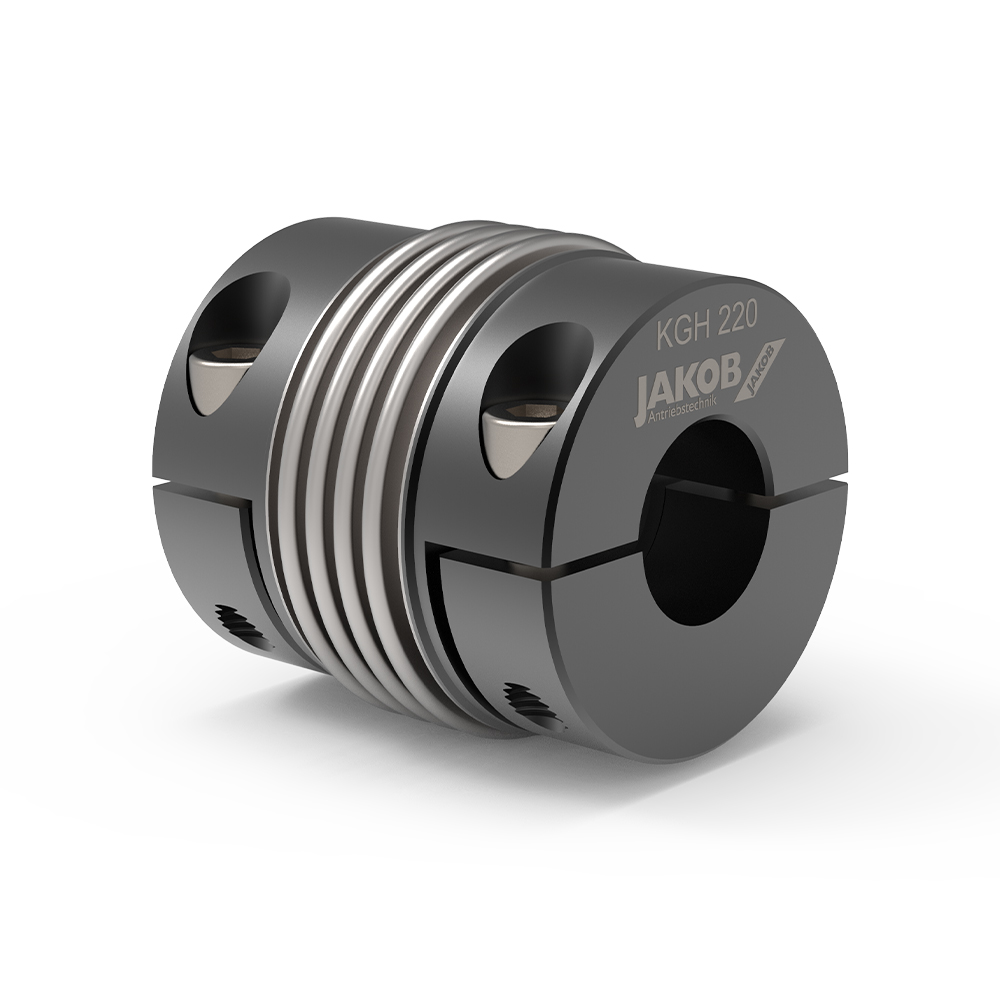

Servo couplings

Large selection & individual solutions

Metal bellows, elastomer, stainless steel, miniature & distance couplings as well as individual custom-made products

Safety couplings

For direct and indirect drives

Large selection of proven series as well as individual custom-made products for every area of application.

Configurator

Find & configure couplings

It’s easy to find the optimal solution from the extensive JAKOB coupling range. For all coupling types.

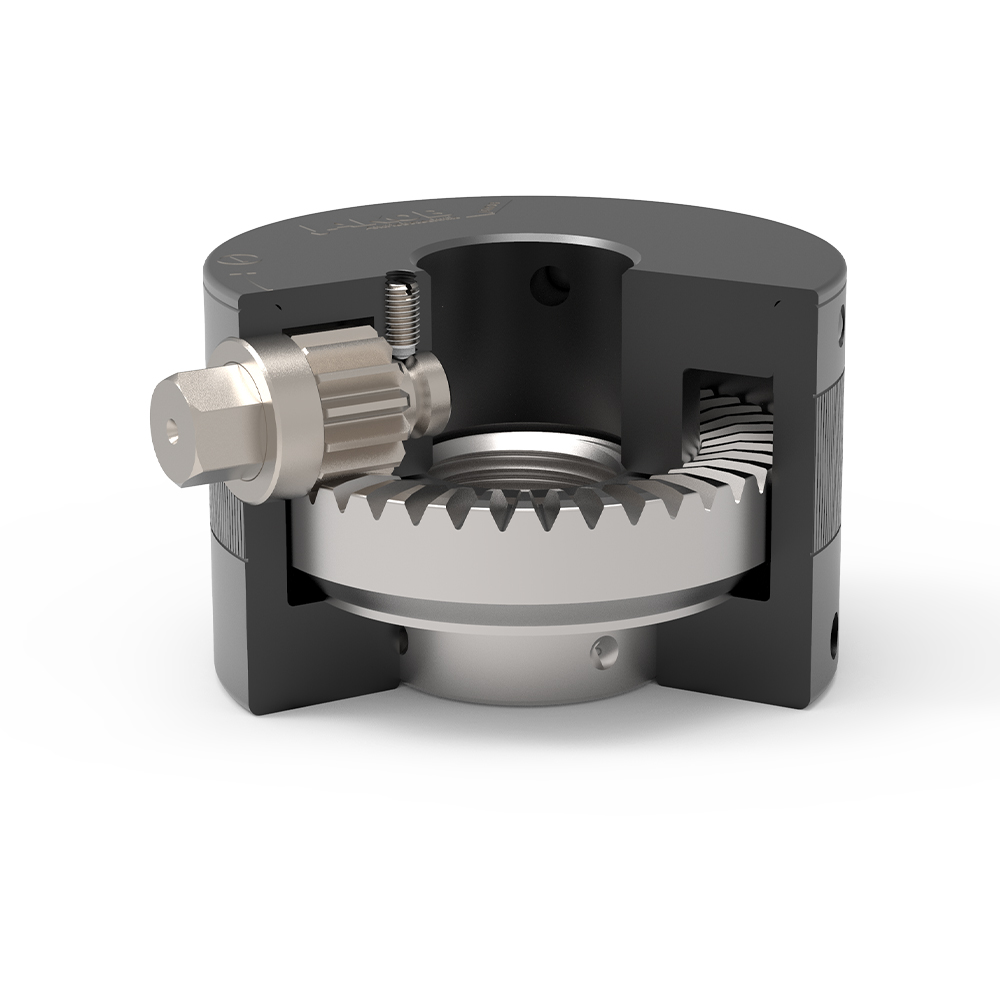

Clamping technology

Clamping & Measurement

Mechanical clamping elements with force amplification, hydromechanical spring clamping systems and clamping hydraulics.

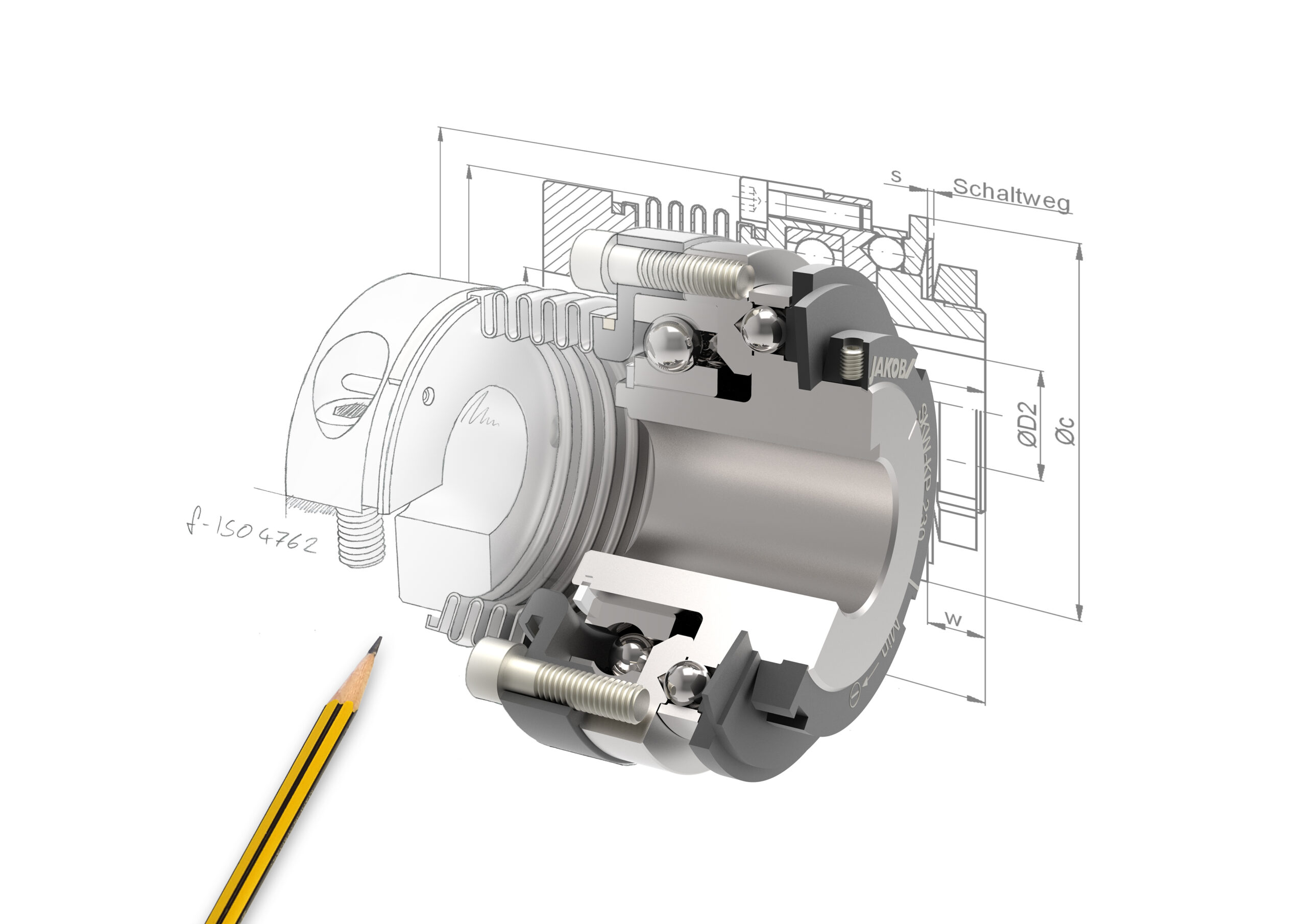

Spindel safety

Motor-Spinlde-Safety-System MS³

The MS³ motor spindle protection system ensures three-dimensional safety for the motor spindle.

From coupling manufacturer to innovation partner

JAKOB Antriebstechnik is your reliable partner in drive technology and clamping elements, and is specialized to realize customized requests. With more than 50 years experience, we are one of the leading suppliers of mechanical components for the servo drive industry. First, our couplings for drive technology set new standards in the market. Our torsional stiff metall bellow couplings are known worldwide. Little by little the product range got bigger. Nowadays we also produce elastomer couplings, miniature couplings for smallest drives and distance couplings for torque transmission at distances up to 6m. We also provide reliable overload protection with our wide safety coupling range.

In the area of workpiece clamping and tool clamping we could establish a wide product range. Wherever workpieces or tools have to be tightened with high clamping forces, clamping elements by JAKOB are used. From power clamping screws and power clamping nuts, which replace their conventionally versions, to power clamping spindles which allow high clamping forces in face plates or jaw boxes, we offer a wide range of clamping products to make working more safe and comfortable. All clamping products by JAKOB offer a sophisticated principle of power amplification which works, depending on the type, in a manual, mechanical or hydromechanical way to generate very high clamping forces.

Now, we developed a Motor-Safety System for spindle protection which emphasizes our high innovative capabilities. In the case of a collision caused overload, the newly developed motor-spindle safety system from JAKOB immediately disconnects the power transmission at the interface between the machine tool headstock and the motor-spindle through 3D-displacement. Therefore the shock-sensitive components of the motor-spindle are effectively protected from the peak impact forces of the tool collision.

JAKOB Antriebstechnik also offers Sectional Rail Couplings that can easily be retrofitted to any current Gripper Rail profile. They’re used when fast joining or disconnecting of section rails is wanted, like in transfer presses. The automatic couplings are applied pneumatically and even close a 5mm-gap between the active and the passive components during the de-clutching. The kinetic clamping ensures the high stiffness and high precision of the connection. The transmission of the clamping force can occur either manually or pneumatically. Available are the types PKH (horizontally) and PKV (vertical) for all common sizes, both in a manual or an automatic version.

We see ourselves as a driver of innovation for new technologies, using all product synergies of the JAKOB group.