products

| servo couplings – shaft couplings Servo couplings are compensating couplings with a backlash free and conformal torque transfer providing high torsional stiffness and a low moment of inertia. The compensating elements as the polyurethane spider and the metal bellows have the ability to compensate misalignment. The area of application ranges from highly dynamic feed drives of the axis in machine tools, to high performance drives in general machine tool design. |

| safety couplings – torque limiters Safety couplings reduce expensive machine damage, repairs and downtime by acting as torque limiters and overload protection. In the event of excessive torque the safety function disengages and the motor gets separated from the drive system. Safety couplings are a life insurance for your machines, no matter whether the error is due to incorrect operation, faulty programming, material overload or tool breakage. |

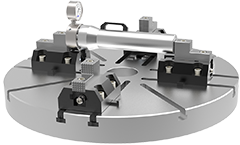

| clamping elements Efficient manufacturing of parts in the metal-cutting and metal-forming industry without quick clamping elements is inconceivable nowadays. Today's requirements go far beyond the handling and operation capacity of conventional clamping elements since higher clamping forces and improved flexibility (due to smaller lot sizes) are in demand. Quick clamping units are necessary to improve the quality of the work place and to further streamline production processes. |

| safety systems Tool collisions with high feed rates cause high impact force peak values on motor-spindles in metal cutting machine tools. As a result, five-figure US-$ amounts for repair and servicing of heavy collision damaged motor-spindle systems and machine tools are common. In the case of a collision-caused overload, the newly developed motor-spindle safety system from JAKOB disconnects the power trans- mission immediately at the interface between the machine tool headstock and the motor-spindle through 3D- displacement. Therefore the shock-sensitive components of the motor-spindle are effectively protected from peak impact forces of the tool collision. |

| example of use Have a look at how our products are used. |