Industry sectors

Machine tools

Maximum precision will always play a major role in the machine tool industry. But new topics such as the increasing need for automation solutions and digitization are also constantly presenting the industry with new challenges. JAKOB can optimally meet this need with high quality and reliable components for the drive.

The torsionally stiff and backlash-free bellows couplings and safety couplings are only manufactured to the highest standards.

If there are higher vibrations and jerky loads in a machine tool, or more precisely in the drive, we can perfectly neutralize these vibrations with our elastomer coupling and safety coupling with elastomer attachment and thus increase the service life of the drive train enormously.

Areas of application:

• Positioning units • Backlash-free gears • Coolant pumps • Spindle protection • Conveyor belt for chips • Lifting tables • Spindle drives (overload protection)

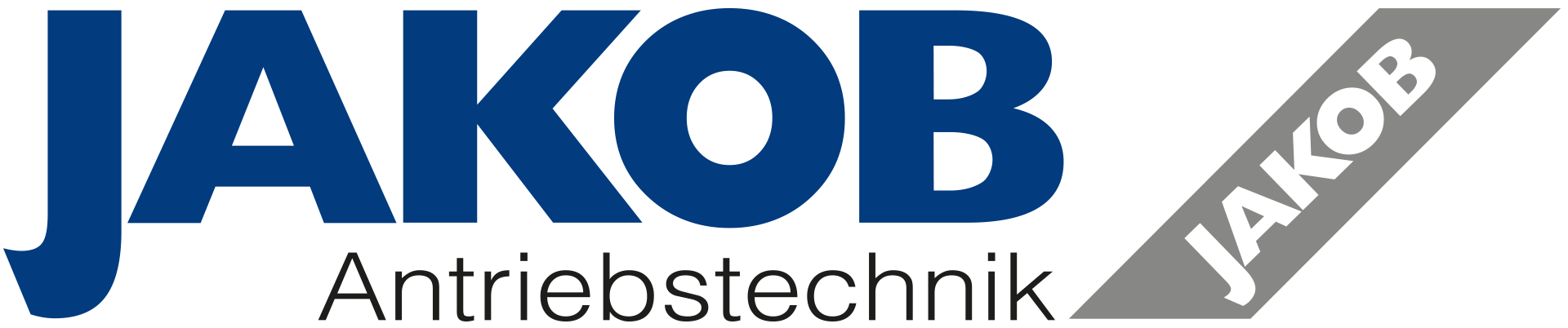

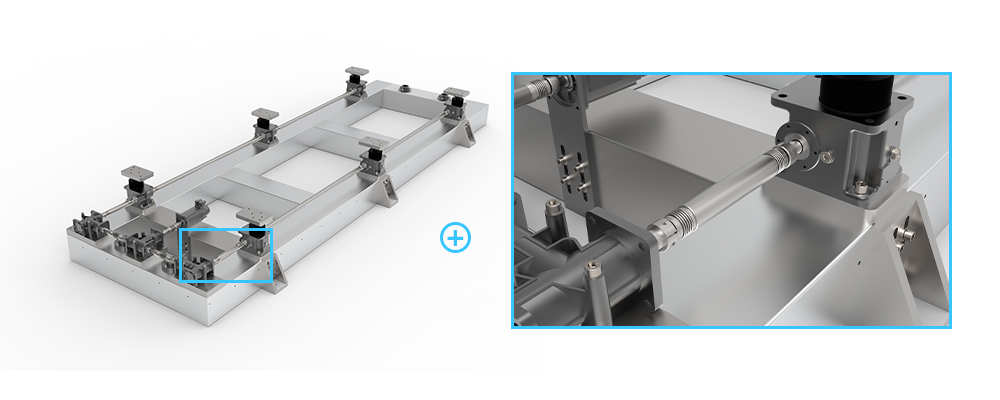

Example operation area – machine tools

Our product portfolio for machine tools

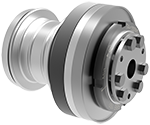

Bellows couplings

• Torques up to 50,000 Nm

• high torsional stiffness

• Temperatures up to 350 ° C

• high speeds

• optional stainless steel versionfor this block. You can use this space for describing your block.

Elastomer couplings

• Torques up to 2,000 Nm

• vibration dampening

• pluggable (blind assembly possible)

• Temperatures up to 120 ° C

• inexpensive

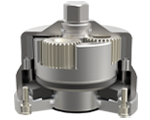

Safety couplings

• Optimal overload and collision protection

• Disengagement torque continuously adjustable

• automatic re-engagement

• Backlash-free, exact torque transmission

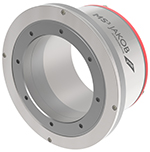

Motor spindle safety

• Safely protects against spindle damage

• Increases machine availability

• Detects tool collisions

Power clamping screws

• very high clamping forces

• maximum operational safety

• large clamping force

• simple operation and assembly

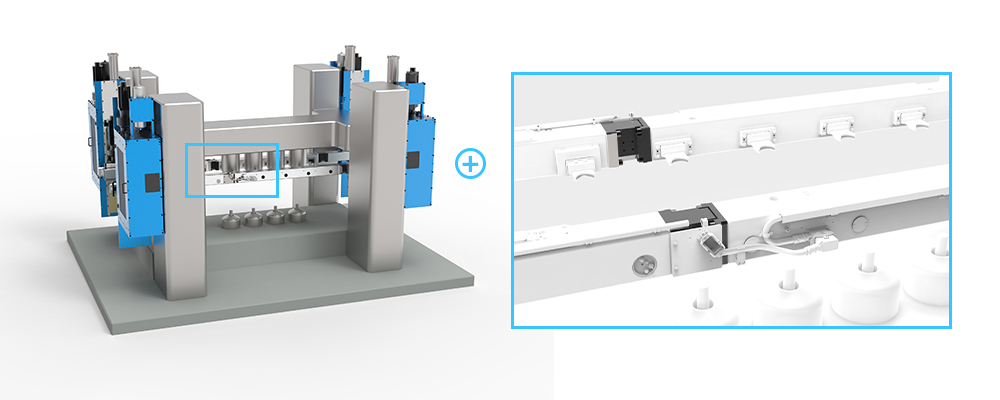

Energy Technology

The technological change is particularly noticeable in the energy sector, not least because of renewable energies, there are always new challenges. At the same time, the systems must be specially protected against failure in order to ensure a constant energy supply. For us, a fail-safe design of our drive units such as spacer couplings, bellows couplings and elastomer couplings is paramount. We also choose a mix of materials to meet requirements such as corrosion resistance, high torques, vibration resistance and long shaft distances. Our products are aimed at manufacturers of energy systems such as cooling tower systems, but also at power plant operators and consulting engineering offices who value simple communication and fast service.

Areas of application:

• Fan drive • Cooling towers • Conveyor belts • Generators • Hydroelectric power plants

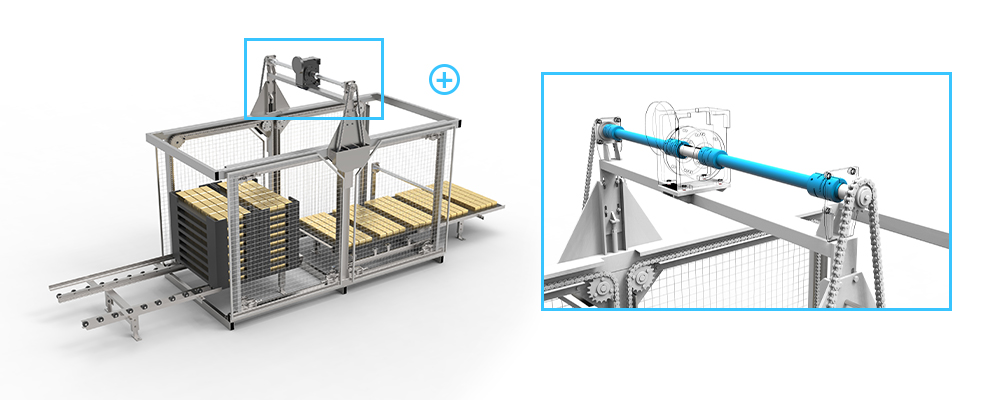

Example operation area – Energy technology

Our product portfolio for energy technology

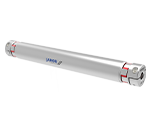

Distance couplings

• Up to 6m length without additional intermediate storage

• increases the service life of the system

• Simpler, easy-to-assemble half-shell hub

(optional cone clamping ring hub)

• Torque range from 120-2900 Nm

• Temperature range -10 ° C to +60 ° C

Elastomer couplings

• Torques up to 2,000 Nm

• vibration dampening

• pluggable (blind assembly possible)

• Temperatures up to 120 ° C

• inexpensive

Bellow couplings

• Torques up to 50,000 Nm

• high torsional stiffness

• Temperatures up to 350 ° C

• high speeds

• optional stainless steel version

Coupling configurator

Find the right coupling for your application

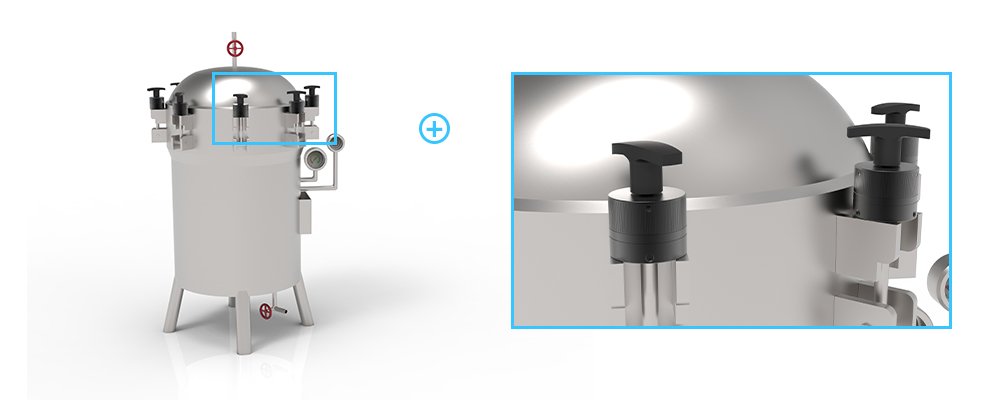

Medical technology

It must be as sterile and germ-free as possible in the production of medical supplies such as medicines. In the applications of medical machines or containers, special attention is paid to hygienic surfaces. Jakob Antriebstechnik has a broad portfolio of stainless steel products for precisely these cases, both in clamping technology and in the field of drive technology. Our clamping technology generates extremely high forces that can prevent leaks, especially in the pressure and vacuum range of medical technology. This enables users to operate their processes with a very high level of accuracy and thus to guarantee the required quality. In addition, the ergonomic handling of a clamping device is of course always an issue. Due to the low tightening torques that are required, operating the clamping nut or screw is child’s play.

Areas of application:

• Tablet deduster • Tablet press • Autoclave • Conveyor belts • Sorting systems

Example operation area – Medical technology

Our product portfolio for medical technology

Distance couplings

• Up to 6m length without additional intermediate storage

• increases the service life of the system

• Simpler, easy-to-assemble half-shell hub

(optional cone clamping ring hub)

• Torque range from 120-2900 Nm

• Temperature range -10 ° C to +60 ° C

Bellow couplings

• Torques up to 50,000 Nm

• high torsional stiffness

• Temperatures up to 350 ° C

• high speeds

• optional stainless steel version

Clamping elements

• highest clamping forces

• high operational reliability

• simple manual operation

• compact, flexible production

Coupling configurator

Find the right coupling for your application

Forming industry

An efficient press line is a key success factor in the metal forming industry; process optimizers talk about the costs per stroke of a workpiece such as a body part. In order to remain competitive, it is therefore important to reduce the costs of the system, especially the main and non-productive times. Rising energy costs must also be taken into account; reducing the weight of the transfer makes it possible to use a smaller torque- or servomotor with lower energy consumption. All of these challenges must be incorporated into our transfer coupling.

That is why we can offer the best solutions with our light and robust transfer couplings to make your system a bit more efficient and also more reliable. Depending on the degree of automation, it is possible to use an automatically clamping coupling or, for simpler systems, to use an easy-to-use manual transfer coupling. In addition, individual energy couplings can easily be mounted on our coupling.

Areas of application:

• press transfer •profile connection • clamping of press tools • workpiece clamping

Our product portfolio for the forming industry

Sectional rail couplings

• self-locking, kinetic wedge-clamping

• pre-centering with alignment pins

• electrical clamping-condition control

• available in steel and aluminum designs

Mechanical clamping

• high clamping forces

• high operational safety

• simple manual operation

• compact and flexible design

Hydromechanical clamping

• mechanical clamping-hydraulical release

• high operational safety

• leakproof and robust

• economical clamping solution

Food industry

Components and systems in the food industry are subject to the constant influence of dirt, dust and aggressive cleaning agents. This is why the “easy to clean” feature must be taken into account during the design phase. At JAKOB, special components are designed in such a way that there are few or no undercuts on the surface of the components in order to keep the cleanability as high as possible (hygienic design). Great attention is also paid to the roughness of the surface in order to prevent microorganisms from settling.

If components have to be dismantled to clean the system, we make it possible to do this quickly and easily and thus not to disrupt the important production process for too long. Finally, some components in our portfolio are made of stainless steel in advance to prevent corrosion during wet cleaning. If our standard product is not made of stainless steel, we are of course ready to design a suitable version for your solution.

Areas of application:

• Meat cutter • Extruder for food and animal feed • Screw drives • Agitators

Our product portfolio for the food industry

Metal bellows couplings

KGH-VA – stainless steel version up to 350°C

Distance couplings

WD-VA – stainless steel version up to 350°C

Safety couplings

Stainless steel and special versions

Clamping elements

MCF-VA – spring clamping nut with integrated disc spring package

Servo industry

In the servo industry, it is all about the absolutely exact movement and positioning of machine parts using servomotors. Great demands are therefore placed on the drive train and its individual components.

In automation technology, machine parts such as the gripper of a robot arm are accelerated and decelerated very quickly, resulting in high overload and holding torques in the drive. In order to meet these requirements, JAKOB Antriebstechnik offers servo couplings with bellows or compensating carbon tubes. Any misalignment in the input and output is compensated for by this, while at the same time it is ensured that the rotary movement is absolutely angularly synchronous. In addition, any heat development during operation must be taken into account. For certain applications, aluminum components are replaced with steel or stainless steel components. The ‘clever’ servo motor in combination with high-quality components is also ideally suited for the requirements of Industry 4.0.

Areas of application:

• Inking rollers of printing machines • Industrial robots • Tool changers • Rotary tables

Our product portfolio for the servo industry

Distance couplings

• Up to 6m length without additional intermediate storage

• increases the service life of the system

• Simpler, easy-to-assemble half-shell hub

(optional cone clamping ring hub)

• Torque range from 120-2900 Nm

• Temperature range -10 ° C to +60 ° C

Bellows couplings

• Torques up to 50,000 Nm

• high torsional stiffness

• Temperatures up to 350 ° C

• high speeds

• optional stainless steel versionfor this block. You can use this space for describing your block.

Title

• excellent dampening capabilities (with elastomer spider)

• high temperatures (with metal bellows)

• blind assembly (with elastomer spider)

• low cost version

Coupling configurator

Find the right coupling for your application

Packaging machines

A packaging machine stands for much more than just packaging products. Other tasks such as sorting, printing, stacking and more are placed on the systems. The machines are used in harsh mechanical engineering environments as well as in absolutely pure chemical or food environments. Since a packaging machine has to take on more and more tasks, the goal is to design the machines as modularly as possible. This allows the user to combine different modules and put together his perfect solution.

JAKOB Antriebstechnik therefore offers modular and at the same time cost-effective components for packaging machines. Good solutions include plug-in elastomer couplings that can be easily fitted over the clamping hub. But spacer couplings with an elastomer star and a simple connecting tube can also be easily used in your application. Safety couplings can also be easily combined with the positive properties of an elastomer attachment, the two components are then joined using a secure flange connection.

Areas of application:

• Sorting system • Labeler • Printing systems • Filling systems • Packers / unpackers

Distance couplings

• Up to 6m length without additional intermediate storage

• increases the service life of the system

• Simpler, easy-to-assemble half-shell hub

(optional cone clamping ring hub)

• Torque range from 120-2900 Nm

• Temperature range -10 ° C to +60 ° C

Safety couplings

• Optimal overload and collision protection

• Disengagement torque continuously adjustable

• automatic re-engagement

• Backlash-free, exact torque transmission

Elsatomer couplings

• Torques up to 2,000 Nm

• vibration dampening

• pluggable (blind assembly possible)

• Temperatures up to 120 ° C

• inexpensive

Coupling configurator

Find the right coupling for your application