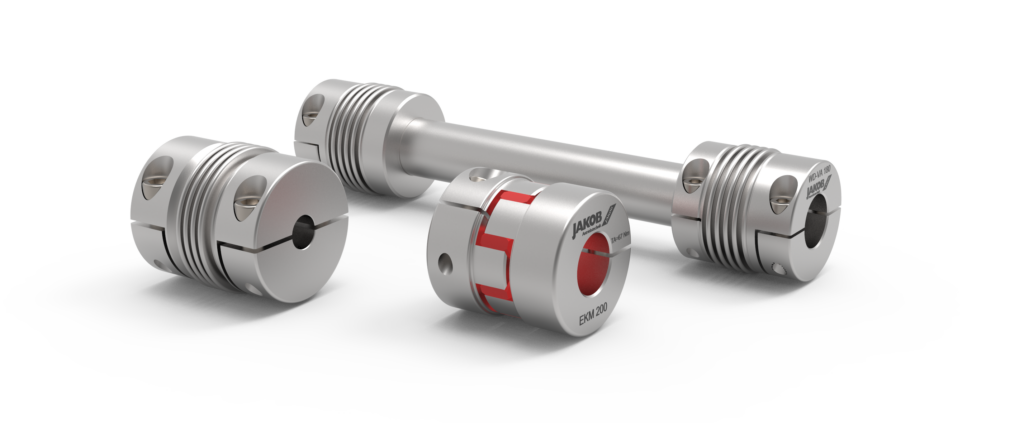

Stainless steel couplings

| configure in coupling finder » | PDF Installation and mounting instructions PDF technical |

|

| EKM-VA • stainless steel version • easy to assemble clamping hub • plug-in, backlash-free and vibration dampening • torque range: 6 - 650 Nm • shaft diameter: 7 - 70 mm | Datenblatt PDF Specification sheet PDF 3D-step-file contact form> |

|

| KG-VA • steel hub - welded design - temperatures up to 350°C • 2-, 4-, or 6-corrugation bellows - short design - high torsional stiffness • Torque range: 30 - 1.000 Nm • Shaft diameter: 10 - 90 mm • stainless steel | Data sheet PDF Specification sheet PDF 3D-step-file contact form> |

|

| KGH-VA • simple installation - split-hub design • wear and maintenance free • variable length stainless steel version up to 350°C • Torque range: 10 - 1.200 Nm • Shaft diameter: 7 - 85 mm | Data sheet PDF Specification sheet PDF 3D-step-file contact form> |

|

| MKG - VA - miniature metal bellows coupling • steel hub - welded design - temperatures up to 350°C • 2-, 4- or 6-corrugation bellows - short design - high torsional stiffness • Torque range: 1,5 - 15 Nm • Shaft diameter: 3 - 20 mm • stainless steel | Data sheet PDF Specification sheet PDF 3D-step-file contact form> |

|

| WD-VA - Metal bellows coupling with intermediate pipe • stainless steel design up to 350°C • backlash free, exact torque transfer • variable length up to 3 m • very easy to fit with splitted hub design • intermediate pipe supply by customer possible • Torque range: 10 - 1200 Nm • Shaft diameter: 7 - 85 mm • temperature range: -40° C to +350° C | Datasheet PDF Specification sheet PDF 3D-step-file contact form> 3D-configurator > |

Stainless steel couplings

JAKOB Antriebstechnik offers some series in stainless steel versions. One of the strengths of the material is its resistance to chemicals, such as those used for cleaning in the food industry.