metal bellows couplings

| go to special solutions » configure in coupling finder » 3D-configurator » | PDF Installation and mounting instructions PDF technical |

|

| KM • simple installation, with EASY-Clamping hub on both sides • 6-corrugation bellows – cost-effective standard series • Torque range: 20 – 1.300 Nm • Shaft diameter: 8 – 85 mm | Data sheet PDF Specification sheet PDF 3D-step-file contact form> 3D-configurator > |

|

| KP • simple installation with radial EASY-clamping hub on both sides • 4-corrugation bellows – short design – high torsional stiffness • Torque range: 25 – 900 Nm • Shaft diameter: 10 – 75 mm | Data sheet PDF Specification sheet PDF 3D-step-file contact form> 3D-configurator > |

|

| KR • simple installation with radial EASY-clamping hub on both sides • straight bellow – long design • low restoring forces – high torsional stiffness • Torque range: 25 – 1.500 Nm • Shaft diameter: 8 – 85 mm | Data sheet PDF Specification sheet PDF 3D-step-file contact form> 3D-configurator > |

|

| KPH /KMH /KRH • simple installation – splitted hub design on both sides • stainless design – variable length • Torque range: 10 – 900 Nm • Shaft diameter: 6 – 55 mm | Data sheet PDF Specification sheet PDF 3D-step-file contact form> 3D-configurator > |

|

| KG • simple installation with radial EASY-clamping hub on both sides • steel hub – welded design – temperatures up to 300°C • 2-, 4- or 6-corrugation bellows – short design – high torsional stiffness • Torque range: 40 – 3.000 Nm • Shaft diameter: 12 – 100 mm » KG-VA = stainless steel optional stainless steel version KG-VA » | Data sheet PDF Specification sheet PDF 3D-step-file Anfrageformular > 3D-configurator > |

|

| KGH • simple installation – splitted hub design on both sides • steel hub – welded design – temperatures up to 350°C • customized length with 2-, 4- or 6-corrugation bellows • Torque range: 20 – 1800 Nm • Shaft diameter: 8 – 85 mm stainless steel version KGH-VA » | Data sheet PDF Specification sheet PDF 3D-step-file contact form> 3D-configurator > |

|

| KG-HS • High-speed version for the highest operating speeds • Rotationally symmetrical clamping hub for optimum balancing quality | Data sheet PDF Specification sheet PDF 3D-step-file contact form> |

|

| KSD • conical hub on both sides • 6-corrugation bellows • Torque range: 10 – 4.000 Nm • Shaft diameter: 6 – 102 mm • cost-effective standard series | Data sheet PDF Specification sheet PDF 3D-step-file contact form> 3D-configurator > |

|

| KSS • conical hub on both sides • straight bellow – long design • Torque range: 25 – 2.500 Nm • Shaft diameter: 10 – 102 mm • low storing forces – high torsional stiffness | Data sheet PDF Specification sheet PDF 3D-step-file contact form> 3D-configurator > |

|

| KXL • Torque range: 4.000 – 70.000 Nm • 3-parted construction- easy to fit – variable in use • flange hub or conical ring hub • Shaft diameter: 60 – 220 mm • backlash free – exact torque transfer • high torsional stiffness – low moments of inertia • high tolerance of shaft displacements | Data sheet PDF Specification sheet PDF 3D-step-file contact form> |

|

| KHS • conical hub on both sides – aluminium design • ”high speed- version” for a speed up to 57.000 rpm • low mass moment of inertia – high balance quality • Torque range: 25 – 700 Nm • Shaft diameter: 6 – 60 mm | Data sheet PDF Specification sheet PDF 3D-step-file contact form> 3D-configurator> |

|

| KPS • for direct mounting in a hollow shaft • 4-corrugation bellows – short design • Torque range: 2 – 600 Nm • Shaft diameter: D1: 3 – 68 mm / D2: 8 – 48 mm • internal axial buffer | Data sheet PDF Specification sheet PDF 3D-step-file contact form> 3D-configurator > |

|

| KPP </span< • several hub variants with a backlash free nose groove principle • blind assembly (plug in) possible – backlash free • sturdy whole metal version for temperatures up to 200°C • Torque range: 10 – 600 Nm • Shaft diameter: 6 – 70 mm | Data sheet PDF Specification sheet PDF 3D-step-file contact form> 3D-configurator > |

|

| KGE • for standardized interface connection DIN – EN – ISO 9409 – 1 • two-part connection flange • compact design • Torque range: 40 – 2000 Nm • shaft diameter: 12 – 90 mm • simple installation with radial EASY-clamping hub at output side | Data sheet PDF Specification sheet PDF Hub-types 3D-step-file contact form> 3D-configurator > |

|

| KE • With flange hubs on both sides for variable attachment • 2 – 4 – 6 – corrugated metal bellows • high operating speeds / rotationally symmetrical design • Customer-specific flange designs available on request | Data sheet PDF Specification sheet PDF 3D-step-file contact form> 3D-configurator > |

go to special solutions »

go to stainless steel types »

configure in coupling finder »

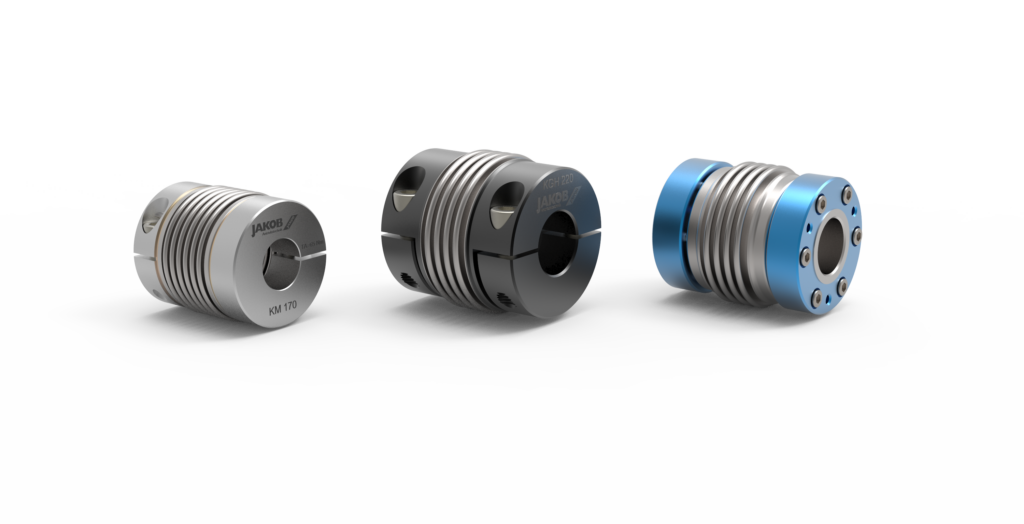

Metal bellows couplings

Servo couplings are compensating couplings for the backlash-free, true-angle transmission of torque with the highest possible torsional rigidity and the lowest possible mass moment of inertia. In line with this claim, JAKOB metal bellows couplings can be regarded as the ideal solution. They have already proven themselves in numerous servo drives for over 40 years. The elastomer couplings with a flexible polyurethane spider can also be a sensible alternative for many applications due to their specific advantages.

Metal bellows couplings are highly flexible all-metal couplings with high torsional rigidity and minimal mass moments of inertia. Cone and clamp connections are available, as well as various metal bellows shapes for a wide variety of applications. What all JAKOB servo couplings have in common is the absolute freedom from play (also shaft-hub connection) and the flexibility to compensate for shaft misalignment. Due to the respective unique selling points of the individual series, the designer will always succeed in finding an optimal solution from the extensive JAKOB coupling range. The areas of application range from highly dynamic feed axes of machine tools to demanding drives in general mechanical engineering.